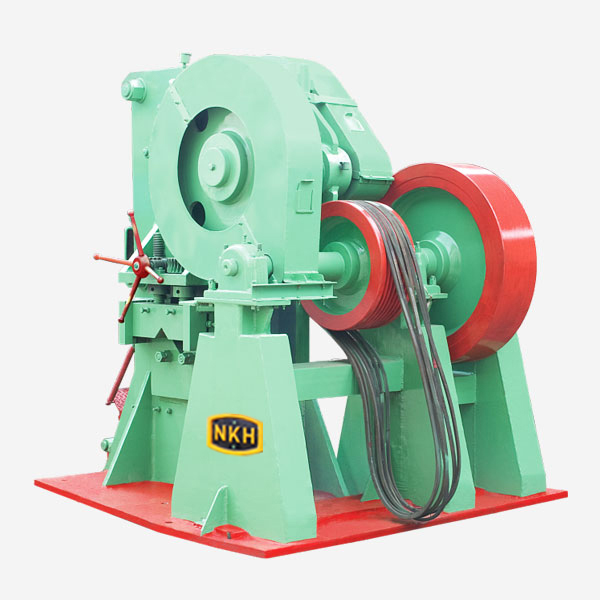

New Automated Billet Shearing Machine

Introducing the New Automated Billet Shearing Machine – a versatile, precision-engineered solution designed to revolutionize the forging industry. This advanced machine is set to replace traditional Band saw and Circular saw machines, offering superior cutting accuracy and efficiency. Our R&D department is actively developing this cutting-edge technology, paving the way for the future of billet processing.How Automated Billet Shearing Machines are better than Standard Shearing Machines?

| Automated Billet Shearing Machine | Standard Billet Shearing Machine |

|---|---|

| Automation: This machine operates with minimal manual input, often controlled by a computer or PLC (Programmable Logic Controller). It automatically feeds, positions, and shears the billets based on pre-programmed settings. | Manual Operation: A standard billet shearing machine typically requires more manual input. Operators need to manually feed the billets, adjust settings, and position the material for each cut. |

| Precision and Consistency: Automation ensures high precision in cutting, with consistent results across large batches of billets. The machine adjusts itself automatically for each cut, reducing human error. | Less Precision: While still capable of making precise cuts, the consistency can vary depending on the skill and attention of the operator. Manual adjustments are more prone to errors. |

| Higher Efficiency: The automation allows for continuous operation with minimal downtime, leading to higher production rates. It can handle large volumes of billets without the need for frequent manual adjustments. | Lower Efficiency: The need for manual intervention slows down the process, especially in high-volume production environments. Downtime between cuts may be longer due to the need for manual setup. |

| Safety: Automated systems often include advanced safety features, reducing the risk of accidents by minimizing direct human contact with the cutting process. | Safety Concerns: Since operators are more involved in the process, there is a higher risk of accidents if proper safety measures are not followed. |

| Integration with Other Systems: Automated billet shearing machines can be integrated with other production line equipment, such as conveyors or robotic arms, for seamless material handling and workflow. | Limited Integration: Standard machines are often standalone units, not integrated with other automated systems, which can limit their efficiency in a highly automated production line. |