NKH Hammers are ideal for hot drop forging, effectively shaping metal into desired forms through the application of heat and force.

Hot Drop Forging

- Home

- Hot Drop Forging

What is Hot Drop Forging

Hot Drop Forging is known for producing high-quality parts with enhanced strength, dimensional accuracy, and improved material properties.

Hot Drop Forging is a specific forging process used to shape metal into desired forms by applying heat and force. Here’s a detailed look at how it works:

Process Overview:

- Heating: The metal workpiece is heated to a high temperature, typically above its recrystallization temperature. This makes the metal more malleable and easier to shape. The heating is usually done in a furnace.

- Dropping: Once the metal reaches the desired temperature, it is placed in a forging die. The die is a specialized tool that has the shape of the final product. A hammer or press then drops onto the metal, applying a significant amount of force. This can be done using a drop hammer, which uses gravity to deliver the force, or a mechanical or hydraulic press.

- Forging: The applied force shapes the metal according to the die’s contours. The metal flows into the die’s cavities, taking the shape of the intended component. This process can be repeated with multiple blows to achieve the desired shape and dimensions.

- Cooling and Finishing: After forging, the metal is allowed to cool. Depending on the material and application, additional heat treatment or finishing processes may be applied to achieve the final mechanical properties and surface finish.

Key Benefits of Hot Drop Forging:

- Enhanced Strength: This process often results in parts with improved mechanical properties, such as greater strength and durability, due to the refined grain structure.

- Precision: The process can produce highly accurate and complex shapes with tight tolerances.

- Material Efficiency: Less material is wasted compared to some other manufacturing processes, as the metal is shaped rather than removed.

- Reduced Post-Processing: In many cases, hot drop forged parts require less machining and finishing, which can lower production costs and time.

Applications:

It is commonly used in manufacturing components for industries such as automotive, aerospace, and construction. Parts like gears, crankshafts, and structural components are often produced using this process.

We will get back to you within 24 hours, or you can call us Mon to Sat, 09:00 AM - 6:00 PM

+91 9888 0000 53

Request A Quote

Please provide details regarding your forging needs and we will work with you to meet your specifications.

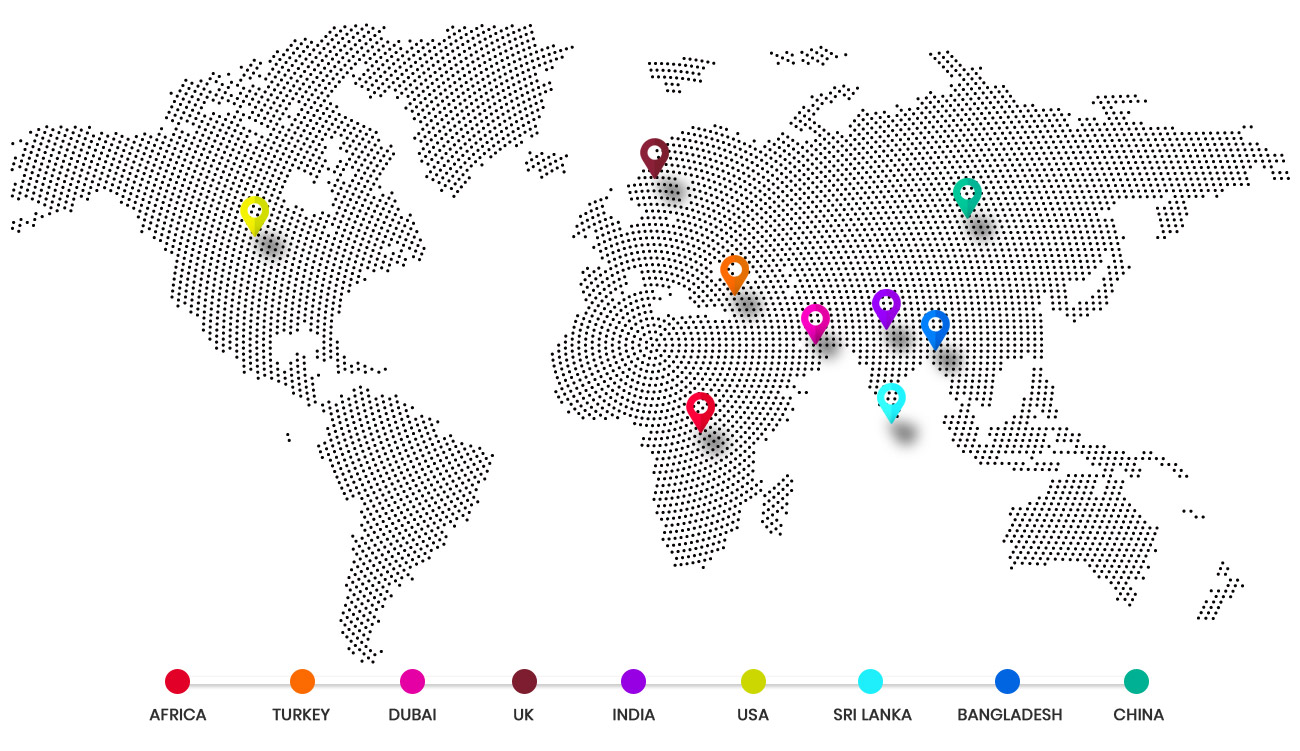

Our Global Clientele