Roll Forge Reducer

- Home

- Case Studies

- Roll Forge Reducer

Roll Forge Reducer

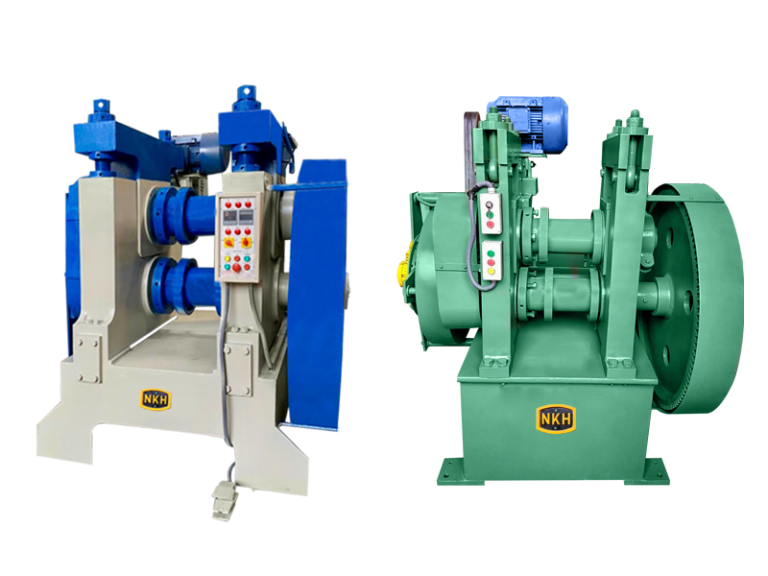

NKH Forging Rolls are designed and constructed with the same engineering excellence that has made NKH leaders in forging machinery. These Forging Rolls employ uncomplicated, highly refined, and rugged designs to maximize user productivity in roll forging parts and forging performing.

Process

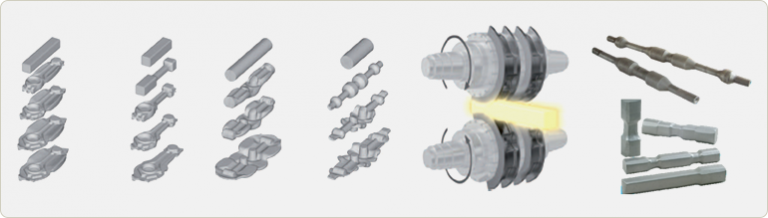

The forging roll is designed for the pre-forming of round and square material, the blank is fed radially into the rollers by an individual or manipulator and pre-formed in individual sectors (passes). The completed blank is then laid on a conveyor and fed to the main forming machine. In addition, roll forging does not require skilled operators or great manual effort. The operator merely grasps one end of the heated stock with tongs and inserts it between the rolls at the "open" position. Die rotation rolls the stock toward the operator who repeats the operation for a specified number of passes.

Rolling processes offer a series of advantages:

- Considerable material savings.

- Improved workpiece surface because of descaling.

- Improved die life in subsequent forging because of descaling and reduction of material flow in the die.

- Helps to produce more uniform quality products.

- Decrease rejections and saves material.

- Increase productivity.

- Skillful operator is not required, and easy to operate, adjust, and install molding fixture

- Dies are exchangeable, and in reverse motion, this is substantially stable and easy to maintain.

Technical Specifications

| Model | Unit | NRF-140 | NRF-170 | NRF-220 | NRF-260 |

|---|---|---|---|---|---|

| Roller Dia | mm | 140 | 170 | 220 | 260 |

| Roll Forging Effective width | mm | 220 | 240 | 260 | 300 |

| Roller Center Distance | mm | 250 | 310 | 360 | 460 |

| Maximum Material Length | mm | 400 | 500 | 600 | 750 |

| Maximum Material Dia | mm | 25 to 30 | 32 to 45 | 45 to 56 | 80-100 |

| Forge Roll Center Adjustment | mm | 5 | 5 | 5 | 5 |

| Clutch Type | Pneumatic | Pneumatic | Pneumatic | Pneumatic | |

| Air Pressure | Kg/Cm2 | 5.5 | 5.5 | 5.5 | 5.5 |

| Stroke per minutes | SPM | 50 | 45 | 45 | 45 |

| Main Motor | Kw | 7.5/10 | 15/20 | 18.5/25 | 30 |

- Specifications are subject to change without prior notice.

- All data is proposal and can be adjusted according to customer’s requirements.