A forging automation research programme at University of Strathclyde has been developed in conjunction with input from world leading companies such as Boeing, Rolls Royce, Timet, Aubert-Duvall and Barnes Aerospace, and formerly, Mettis Aerospace. The industrial input formed a key part of the research agenda based on a membership model [55]. As part of that process a requirement to pursue advanced automation techniques was identified as part of a strategic road-mapping exercise and this resulted in a creation by the author of a vision for Automation by the author to encapsulate the main objectives for Automation in AFRC.

It was clear from industrial interaction that manual variability in forging in particular is a key determinant of inconsistency in product quality and for a research organisation attempts to generate process improvements can be masked by the associated indeterminism. Some operators take longer to transport part from furnace to press, even a single operator has variability in the associated processing time dependent on levels of tiredness, and other external factors. Thus part temperature – a key determinant of forging quality and grain size is difficult to control at the point of hit, regardless of how much effort is placed on temperature control at the oven, since the transport time is variable.

Process variability in manually dominated processes has been widely observed by work study exercises and is a feature of simulation exercises in manufacturing [56, 57]. For the process experimenter this variability is anathema in the isolation of improvements so as part of the technological development of advanced forging and forming. Accordingly the key vision of the AFRC automation then evolved into a two-pronged approach, that of developing and researching advanced automation techniques in their own right, and to attempt to expunge, or at least to mitigate, the inherent variability in forging techniques by repeatable, automated, usually robotic approaches.

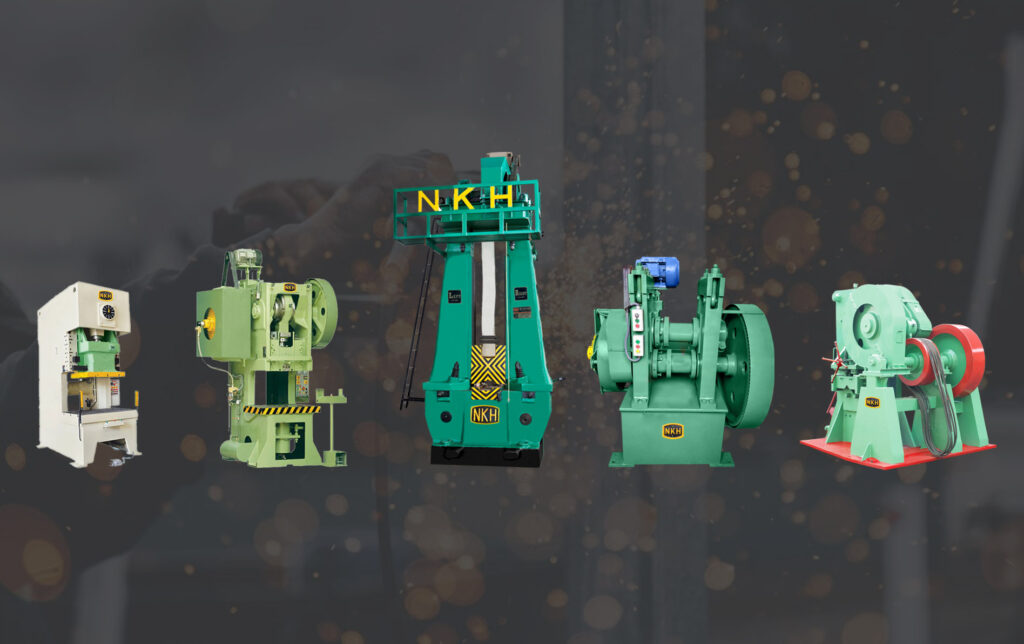

This vision was then discussed and presented internally so that agreement on the strategic thinking could be embedded in the senior management of the industrial partners, key to assuring the success of the project. Management buy-in is essential from the earliest possible stage in order to ensure the viability of the project when the going gets difficult. A pilot project was selected see Figure 11, and detail associated with the project is presented in the following section.